May 27, 2025

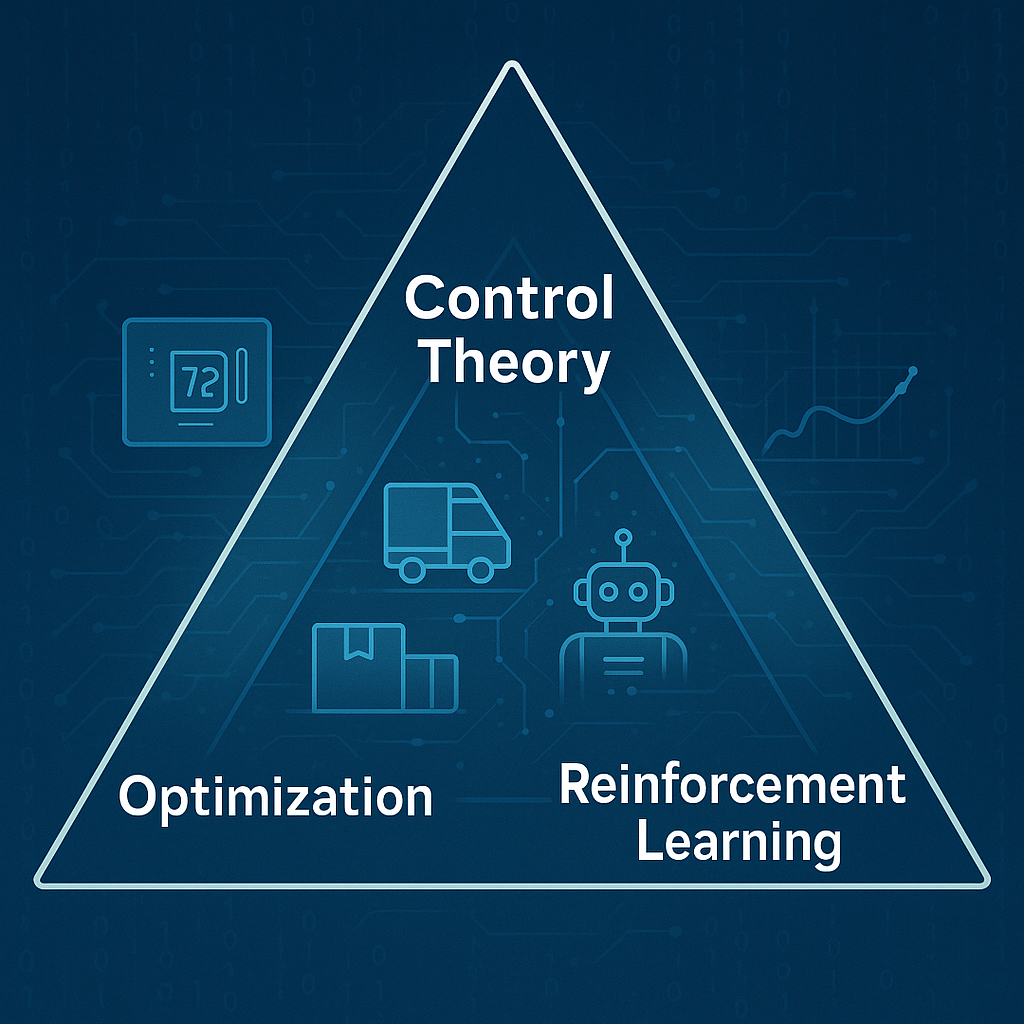

While everyone’s talking about ChatGPT and generative AI, the real revolution in supply chain management is happening through three mathematical principles that most executives have never heard of. These aren’t abstract academic concepts. They’re the secret weapons that separate supply chain leaders from followers in the age of AI.

The truth is, general-purpose AI tools like large language models are impressive, but they fall short when it comes to the complex, dynamic challenges of modern supply chains. To build truly autonomous supply chain systems that can sense, decide, and act with minimal human intervention, you need to understand the mathematical foundations that power specialized AI systems.

1. Control Theory: The Art of Self-Regulating Systems

Think of your home thermostat. It maintains a perfect 72 degrees by constantly sensing temperature, comparing it to your target, and adjusting the air conditioning accordingly. When someone opens a window on a hot day, the system automatically compensates. This is control theory in action—and it’s revolutionary for supply chain management.

Game-Changer for Replenishment: Traditional inventory systems react to stockouts after they happen. Control theory enables predictive replenishment systems that sense demand fluctuations, compare them to optimal inventory levels, and automatically adjust ordering patterns before problems occur. Imagine a system that detects early signals of demand spike—like increased web traffic or seasonal patterns—and begins ramping up inventory before your competitors even notice the trend.

Distribution Revolution: Control theory transforms distribution from reactive to adaptive. Instead of fixed routing schedules, your distribution network becomes a self-regulating system that continuously optimizes based on real-time conditions. When traffic patterns change, weather disrupts routes, or demand shifts geographically, the system automatically rebalances without human intervention.

Perishables Transport Mastery: Here’s where control theory becomes truly powerful. Managing perishables is like maintaining multiple thermostats simultaneously including temperature, humidity, timing, and freshness all need precise control. Advanced control systems can predict spoilage rates, optimize transport conditions in real-time, and even reroute shipments to minimize waste. One major grocery chain reduced perishable waste by 40% using control theory-based systems that automatically adjust transport conditions based on product type, external temperature, and estimated delivery time.

The key insight: poorly designed control loops can create chaos. We’ve all seen inventory systems that oscillate between stockouts and overstock. Control theory provides the mathematical tools to ensure stability and reliability in your autonomous supply chain operations.

2. Optimization Theory: Finding the Best Path Forward

If control theory keeps your systems on track, optimization theory finds the best possible track in the first place. Every supply chain decision involves trade-offs with finite resources, and optimization provides the mathematical framework for making these decisions optimally.

Replenishment Game-Changer: Traditional replenishment follows simple rules, such as reorder when inventory hits a certain level. Optimization theory enables multi-objective replenishment that simultaneously minimizes carrying costs, maximizes service levels, and reduces supply risk. The math considers hundreds of variables: seasonal demand patterns, supplier reliability, storage costs, and even market volatility to determine not just when to order, but how much, from which suppliers, and through which channels.

Distribution Optimization: Beyond basic route optimization lies something far more sophisticated: dynamic network optimization. These systems consider real-time traffic, fuel costs, driver availability, customer priorities, and delivery time windows to continuously optimize your entire distribution network. UPS’s ORION system, built on optimization principles, saves the company over $400 million annually by finding mathematically optimal routes.

Perishables Complexity: Optimizing perishable transport involves solving what mathematicians call a “multi-objective optimization problem under uncertainty.” The system must balance delivery speed (minimize spoilage) against fuel costs, route efficiency against product quality, and customer satisfaction against operational costs. Advanced optimization algorithms can solve these complex trade-offs in real-time, often finding solutions human dispatchers would never consider.

The breakthrough comes with stochastic optimization—optimization under uncertainty. Instead of assuming fixed demand, these systems work with probability distributions, creating robust solutions that perform well across various future scenarios. Your supply chain becomes antifragile, actually benefiting from volatility.

3. Reinforcement Learning: Systems That Learn and Adapt

Here’s where AI gets truly intelligent. Reinforcement learning enables systems to learn optimal behaviors through trial and error, receiving rewards for good decisions and penalties for poor ones. Unlike other AI approaches that require massive labeled datasets, reinforcement learning agents learn by doing.

Adaptive Replenishment: Imagine an inventory system that learns your customers’ behavior patterns, seasonal fluctuations, and supplier reliability through experience. It starts with basic rules but continuously improves its decisions based on outcomes. When a new product launches or market conditions change, the system adapts its replenishment strategy automatically. No retraining required.

Intelligent Distribution: Reinforcement learning transforms distribution networks into learning systems. The AI agent tries different routing strategies, observes results (delivery times, fuel costs, customer satisfaction), and evolves its approach. Over time, it develops sophisticated strategies that account for factors human planners might miss, for example, which customers are flexible with delivery times or which routes perform better during specific weather conditions.

Perishables Learning: This is where reinforcement learning shines brightest. Managing perishables involves countless variables that change constantly, such as temperature sensitivity varies by product and season, customer preferences shift, and transportation conditions fluctuate. A reinforcement learning system learns the optimal balance through experience, developing strategies that minimize waste while maximizing freshness and customer satisfaction.

The critical insight is the exploration-exploitation dilemma. Should your automated systems stick with proven strategies (exploitation) or try new approaches (exploration)? Smart RL systems balance this trade-off, ensuring continuous improvement while maintaining reliable performance.

The Integration Advantage

The real power emerges when these three mathematical foundations work together. Control theory provides stability, optimization finds the best strategies, and reinforcement learning enables continuous adaptation. Together, they create supply chain systems that are not just automated, but truly autonomous that are capable of sensing market changes, making optimal decisions, and learning from experience.

Companies implementing these integrated approaches report 25-40% improvements in inventory turns, 15-30% reductions in transportation costs, and up to 50% decreases in perishable waste. More importantly, they’re building supply chains that get smarter over time, creating sustainable competitive advantages that generic AI simply cannot match.

The future belongs to supply chain leaders who understand that the real AI revolution isn’t about chatbots It’s about designing models that enable truly intelligent, autonomous operations. The question isn’t whether these technologies will transform supply chain management, but whether you’ll be leading that transformation or trying to catch up.